|

|

Pfannenberg 4th Generation Filterfans

More Safety in the Production Process - User Report

|

|

Dear reader,

The basic problem when using filterfans to cool switch cabinets is primarily ambient strain. The filter mats in fans often clog up very quickly. The consequence: cooling fails, the switch cabinet overheats, and you are threatened with cost-intensive down times. The new, 4th

Generation Pfannenberg filterfans effectively work against this.

|

|

|

| In the Wismar plant of derived timber product manufacturer Egger, the new

4th Generation Pfannenberg filterfans were successfully tested under the toughest ambient conditions. |

|

Groundbreaking innovation approved by the industry

The company is active throughout Europe, employing 800 workers in Wismar alone, and uses the most up-to-date technology to produce the highest quality of products. Alongside environmental friendliness, the efficient use of energy and raw materials is a priority focus. It is no wonder then that Egger turned to Pfannenberg in the search for highly effective filterfans.

|

|

|

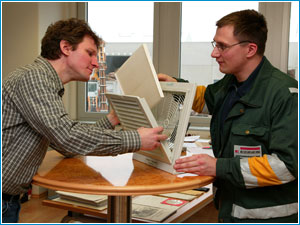

- Daniel Voigt presents the assets of the new fourth Generation Pfannenberg filterfans to Tobias Zimmermann, the assistant plant manager for technology.

- "The fourth generation of Pfannenberg filterfans completely won me over during the field test." (Daniel Voigt, electronic technician)

|

|

| Read the entire article (English translation,

original German text) |

|

New patented filter mat and louvre design

Contrary to regular IP 55 filterfan-systems, the new Pfannenberg IP 55 solution does not reduce the air throughput of the system. Due to an optimized air routing and innovative, patented filter mat design, the Pfannenberg 4th Generation Filterfans not only provide an 100% increase of air throughput at IP 55 but also a longer service life, resulting in less maintenance downtime. The summary of Egger after 20 weeks of testing:

|

|

|

- Extension of service intervals from one to two weeks – sometimes even every three weeks.

- Reduction in time expenditure through comfortable compressed air cleaning; simple tool-free assemble, maintenance and operation of filterfans; time saving through omission of inconvenient filter mat blanks.

- Leading to more safety in the production process; saving time and money.

|

|

|

Additional information on the 4th Generation Filterfans ... |

|

|

|

|

Benefit from our core competency to increase the availability of your machines and at the same time reduce production costs by decreasing the service and maintenance cycles.

|

|

|

From time to time we would like to inform you on news, products and events. If you would like to subscribe to a different newsletter topic or do not like to receive this e-newsletter anymore, please click here:

Newsletter Administration.

Pfannenberg Group - Werner-Witt-Straße 1 - 21035 Hamburg, Germany

Tel.: +49 40 / 7 34 12 - 214, Email:

Newsletter@Pfannenberg.com

© 2008 - All rights reserved - Internet: http://www.pfannenberg.com |

|

|

|

|